The Hemho centrifuge series is an improved version of LWL inverted model, which solves the shortcomings of LWL series. Due to the problem of handling capacity, simplified differential, lubrication system and other devices. Easy to carry, and can achieve the same functions as LWL series, used in enterprises and institutions research and development laboratory research and development work.

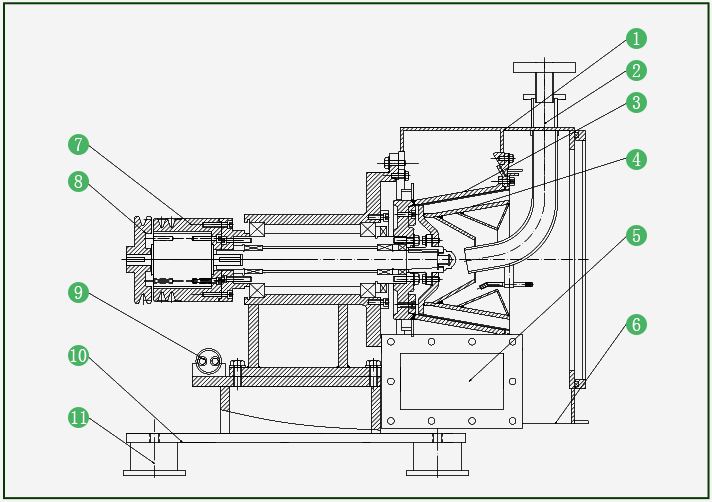

Suspension from a feeding tube into the spiral front-end, the preliminary accelerated into the drum, drum air flow under the action of centrifugal force field in the slurry liquid phase by setting the screen mesh is on the wall of separation, solid phase particles are trapped inside the drum;At the same time, the drum of solid phased particles in centrifugal force and spiral drum under the action of the differential between the small drum to the drum heel movement, in the process of the movement, because of the turning diameter increased, increasing centrifugal force to get fast, solid phase from the initial to the high moisture content of solid phase to the discharge when the drum to solid phase, low moisture content so as to realize the separation of solid and liquid automatic, continuous.

Corrosion Resistant Material

Corrosion Resistant Material

Drum, screw and other main parts can be corrosion-resistant stainless steel, titanium alloy manufacturing.

Special Filter Screen

Special Filter Screen

Special filter, filter thickness is 0.5 mm, 10-250 mesh sieve density optional, longer service life.

Stepless Speed Regulation

Stepless Speed Regulation

Stepless speed regulation of drum speed.

Circulating Lubrication

Circulating Lubrication

Simple reliable circulation lubrication lubrication wa.

Other Systems

Other Systems

Simple and reliable way of circulation lubrication, including surge tank, oil filter and water cooling system.

Safety Protection

Safety Protection

Speed detection, oil free protection, motor overload overheat protection, spiral zero differential protection.

Successful Application Cases

Successful Application Cases

Horizontal spiral screen centrifuge has been widely used in chemical industry, food, salt, mining, pharmaceutical and other industries. Like LWL series centrifuge, it has strong pertinence to material, so material analysis and corresponding experiment should be carried out in the selection process to determine its applicability and separation performance.

Metal screen porosity

Metal screen porosity

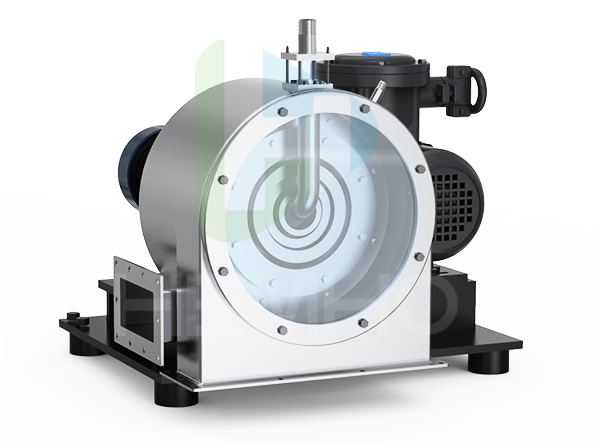

MY series adopts screen filtering and spiral unloading method, and the minimum pore of the metal filter can be achieved to 0.07mm. Widely used in the separation of crystals and fibers. It plays a very important role in the small handling capacity or determining the material separation characteristics of many domestic enterprises.

| Model |

Bowl Diameter (mm) |

Speed (r/min) |

Processing Capacity(L/H) |

Separation Factor |

Power of Motor(kw) |

Weight (kg) |

Dimension (mm) |

|

|

|

| MY100 | 100 | 6500 | 20-100 | 2364 | 0.4 | 50 | 530X370X270 |

|

|

|

| MY150 | 150 | 5200 | 50-300 | 2270 | 0.7 | 120 | 720X550X420 |

|

30 Year Brand

Contact Us