The centrifuge equipment is implemented in accordance with the JB/T10769.1-JB/T10769.2-2007 manufacturing standard, and the airtightness, explosion-proof, balance accuracy, and safety performance meet the relevant regulations of GB19815-2005.

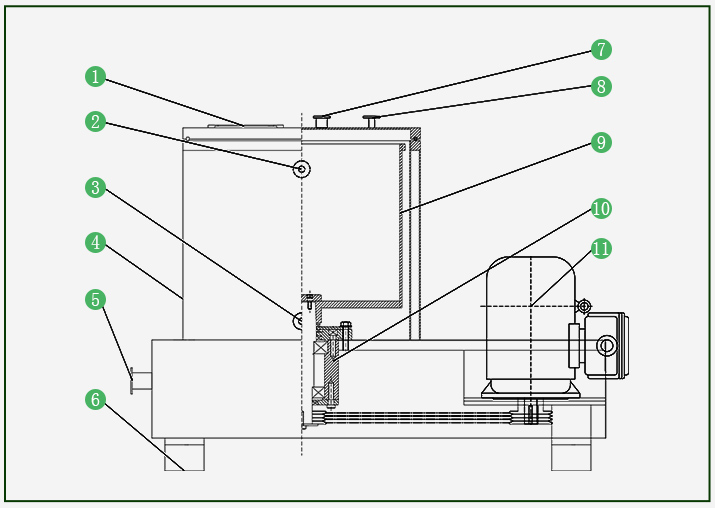

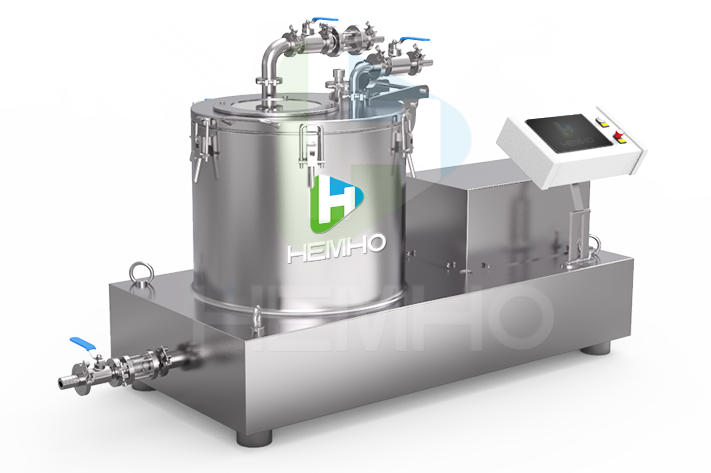

HH series centrifuges are specially designed for plant extraction, with airtight, explosion-proof and clean functions. The HH series centrifuge adopts a flat-bottomed drum structure, with larger volume, higher cleanliness, and pollution-free structure design. With simple operation, clean appearance, stable and excellent performance, it is liked by consumers.

The operator fills the filter bag with crushed plant material and puts it in the machine. Then, add alcohol until the plant material is submerged, and set the program to rotate in both directions to fully extract the effective ingredients in the plant. Open the bottom valve to release the extract, and the plant material is rotated at high speed to remove the liquid as much as possible. Then the alcohol lotion is further processed.

Low Temperature

Low temperature acceptable-70℃ to 70℃.

The Large Sight Glass

The large sight glass structure allows a clear view of the situation inside the equipment.

Fully Automatic and Manual

Fully Automatic and Manual

Fully automatic extraction process, the program can set the rotating drum forward and reverse rotation speed, time and cycle times, and can switch to manual control.

Adjust

Adjust

Dehydration speed and time can be set.

Data Display

Data Display

Temperature display,vacuum pressure display.

Single Person Operation

Zipper type filter bag can be loaded and unloaded quickly,designed for single person operation.

Another Optional Configuration

Another Optional Configuration

Another optional configuration: oxygen content detection and protection system, cart structure.

| Model |

Bowl Diameter (mm) |

Speed (r/min) |

Drum Height (mm) |

Separation Factor |

Drum Volume (L) |

Coolant Volume (L) |

Feeding (kg) |

Power of Motor (kw) |

Weight (kg) |

Dimension (mm) |

| HH15 | 300 | 2000 | 250 | 671 | 12 | 6 | 3 | 1.1 | 240 | 1000x500x650 |

| HH25 | 300 | 2000 | 400 | 671 | 25 | 8 | 5 | 1.5 | 260 | 1000x500x750 |

| HH45 | 450 | 1500 | 290 | 566 | 45 | 16.5 | 10 | 2.2 | 380 | 1250x700x750 |

| HH65 | 450 | 1500 | 400 | 566 | 65 | 21 | 12 | 3 | 410 | 1250x700x850 |

| HH115 | 600 | 1250 | 390 | 524 | 115 | 28 | 23 | 4 | 800 | 1400x900x950 |

| HH145 | 600 | 1250 | 500 | 524 | 145 | 34 | 28 | 5.5 | 820 | 1400x900x1050 |

| HH250 | 800 | 1120 | 610 | 561 | 250 | 45 | 50 | 11 | 1350 | 1800x1100x1200 |

| HH480 | 1000 | 1000 | 590 | 559 | 480 | 60 | 70 | 15 | 2000 | 2100x1350x1350 |

| HH860 | 1250 | 950 | 700 | 630 | 860 | 70 | 90 | 18.5 | 2500 | 2300x1600x1700 |

30 Year Brand

Contact Us