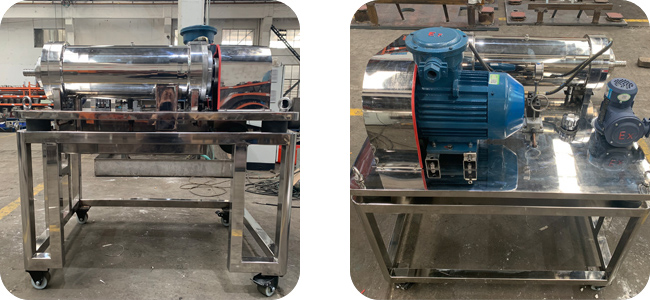

Introductin of Typical Cases of Laboratory Decanter Centrifuges - HY Series

Separate materials: barium carbonate, titanium dioxide, potato starch

Brief description of the process:

The working principle of the decanter centrifuge is simple and has been known to the public for a century. The drum and spiral are supported by separate suspensions, and the material enters through the inlet tube and is accelerated by the drum into the core drum body. The core section consists of a cylindrical and conical rotating drum where the centrifuge forces deposit solid material on the drum walls. The spiral body has the same shape and angle as the drum and rotates at a slightly faster speed than the drum, allowing the separated solids to be pushed towards the narrow conical end and discharged from the drum.

Technical features:

1. Universal sedimentation centrifuge.

2. Fast disassembly and assembly - within 30 minutes.

3. Minimal material residue, spiral to drum clearance less than 0.3mm.

4. Compact design, easy-to-understand control panel and operation.

5. High separation factor, no need to use filter media.

Brief description of the process:

The working principle of the decanter centrifuge is simple and has been known to the public for a century. The drum and spiral are supported by separate suspensions, and the material enters through the inlet tube and is accelerated by the drum into the core drum body. The core section consists of a cylindrical and conical rotating drum where the centrifuge forces deposit solid material on the drum walls. The spiral body has the same shape and angle as the drum and rotates at a slightly faster speed than the drum, allowing the separated solids to be pushed towards the narrow conical end and discharged from the drum.

Technical features:

1. Universal sedimentation centrifuge.

2. Fast disassembly and assembly - within 30 minutes.

3. Minimal material residue, spiral to drum clearance less than 0.3mm.

4. Compact design, easy-to-understand control panel and operation.

5. High separation factor, no need to use filter media.

HY series high performance small decanter centrifuges are commonly used in the food fermentation industry, fine chemical pharmaceutical and biotechnology industries, in addition to the research and development sector. HY series centrifuges are also used in the production of high quality products with a flow rate of less than 500 L/H. HY series centrifuges can also be used as measuring instruments to record the two-phase flow characteristics of the test product and the change in torque and power consumption of the spiral, from The flow behavior of the product is modified for the process.